Boron Carbide Nozzle Sandblasting nozzle Boron Carbide Venturi Nozzle hotpress process

Thông tin chi tiết sản phẩm:

| Place of Origin: | China boron carbide ceramic nozzle for sandblasting |

| Hàng hiệu: | High Broad sandblasting nozzles factory |

| Chứng nhận: | ISO, DNV,BV sandblasting nozzles |

| Model Number: | sandblasting boron carbide nozzle with aluminium jacket |

Thanh toán:

| Minimum Order Quantity: | 10 pieces |

|---|---|

| Giá bán: | Có thể đàm phán |

| Packaging Details: | Each nozzle packed in a plastic tube, then in a carton |

| Delivery Time: | 500 pieces:15 Days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union, MoneyGram,PayPal |

| Supply Ability: | 1000 pieces per month |

|

Thông tin chi tiết |

|||

| Name: | Hotpress Sandblasting Boron carbide sand nozzles | Advantage: | Durable & Wearable Boron Carbide Ceramic Sandblasting Gun Nozzles With Pefect Abrasion |

|---|---|---|---|

| Material: | sandblasting Boron carbide nozzle with aluminium jacket | Shape: | Straight Core,Ventui Type silicon carbide sandblast nozzle |

| Type: | Doule Venturi,single Entrance boron carbide nozzle | Usage: | Sandlbast Machine, Shot Gun,Sandblasting Gun,Spray Water, Cleaning Machine |

| Thread: | Coarse thread, thin thead, fine thread | Rubber jacket: | Coarse thread long venturi boron carbide rubber jacket sand blast nozzles |

| boron carbide nozzle: | sandblasting nozzle | ||

| Làm nổi bật: | silicon carbide nozzle,ceramic sandblast nozzle |

||

Mô tả sản phẩm

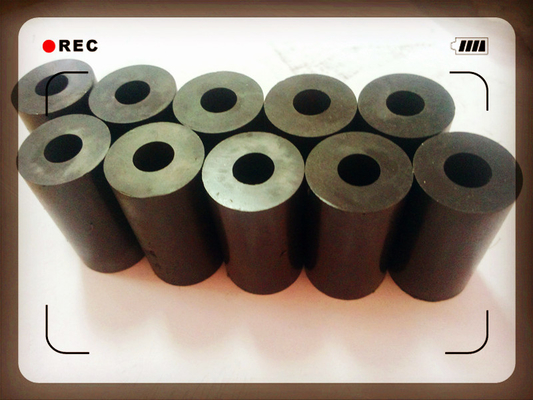

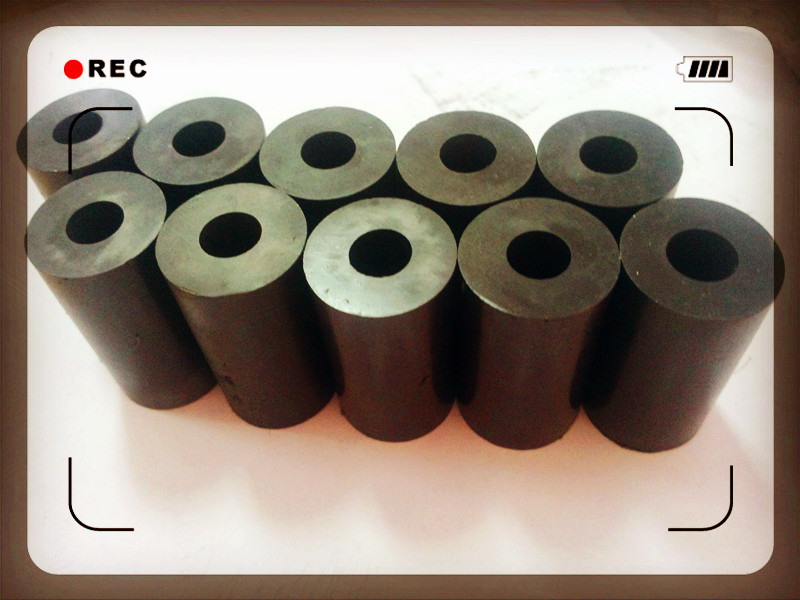

Boron Carbide Ceramic Nozzle for sandblasting

High hardness, Low density, High temperature resistant, Excellent wear and anti-corrosion.

Specifications

a) High abrasion resistance, high using life.

b) High hardness and high strength

c) High chemical corrosion.

d) Light weight

Sand Blasting Boron Carbide Nozzle

This kind of nozzle is made from boron carbide by hot pressing with straight bore and venturi bore type. Because of its hardness, low density, high temperature resistance, excellent wear and anti-corrosion, Boron Carbide Nozzle has been widely used in sandblasting and shot peening equipments, offering a longest life with optimum air and abrasive use.

Products application:

Equipped on the blasting machine and used as sand blasting.

Can be used to remove rust, water cutting etc.

boron carbide venturi nozzle size

| Type | Outer diameter | Inner diameter | Length |

| N35021 | 21.0 | 5.0-10.0 | 35.0 |

| N60021 | 21.0 | 5.0-10.0 | 60.0 |

| N82021 | 21.0 | 5.0-10.0 | 82.0 |

| N100021 | 21.0 | 5.0-10.0 | 100.0 |

| Type | Outer diameter | Inner diameter | Length |

| N35021A | 21.0 | 5.0-10.0 | 35.0 |

| N60021A | 21.0 | 5.0-10.0 | 60.0 |

| N82021A | 21.0 | 5.0-10.0 | 82.0 |

| N100021A | 21.0 | 5.0-10.0 | 100.0 |

| Type | Horn diameter | Inner diameter | Length |

| N54032 | 15.0 | 3.2 | 54.0 |

| N54048 | 15.0 | 4.8 | 54.0 |

| N54064 | 15.0 | 6.4 | 54.0 |

| N54079 | 15.0 | 7.9 | 54.0 |

| N54095 | 15.0 | 9.5 | 54.0 |

| N54111 | 15.0 | 11.1 | 54.0 |

| N54127 | 15.0 | 12.7 | 54.0 |

| N150032 | 15.0 | 3.2 | 150.0 |

| N150048 | 15.0 | 4.8 | 150.0 |

| N150064 | 15.0 | 6.4 | 150.0 |

| N150079 | 15.0 | 7.9 | 150.0 |

| N150095 | 15.0 | 9.5 | 150.0 |

| N150111 | 15.0 | 11.1 | 150.0 |

| N150127 | 15.0 | 12.7 | 150.0 |

| Type | Exit | Inner diameter | Length |

| N130048 | 9.0 | 4.8 | 130.0 |

| N135064 | 10.5 | 6.4 | 135.0 |

| N140079 | 12.0 | 7.9 | 140.0 |

| N165095 | 14.0 | 9.5 | 165.0 |

| N190111 | 15.5 | 11.1 | 190.0 |

| N215127 | 17.0 | 12.7 | 215.0 |

Note: not all the types and sizes are showed in here. Other shapes and sizes are also available upon request and welcome OEM&ODM.

![]()

![]()

![]()

![]()

Product features:

High abrasion resistance, high using life

High hardness and high strength

High chemical corrosion

Light weight

Advantages

1. Longer service life. In terms of service life, boron carbide nozzle has the longest one such as for sand

blasting and shot peening.

2. Lower cost per use. Boron carbide costs more but will outlast tungsten carbide by 3 to 10times.

3. To reduce down time.

4. To maintain efficiency.

Company Principle:

Our Belief: Continuous Innovation.

Our Spirit: Sincerity, Unity, Dedicated, Hardworking.

Our Mission: Provide most advanced products & most professional technical solution.

Contact us:

Lucky Liu

E-mail:highbroad1@vip.163.com

Telephone: +86-731-85717705

Mobile Phone:+86-15575935462

Fax: 86-731-85716569

Address: 70 Chezhan North Road,Changsha,Hunan

Zip: 410100